Regarding the supercritical midsole foaming technology, the more popular terms and propaganda content can be said to be supercritical nitrogen foaming. Nitrogen foaming in the middle can bring a soft cushioning foot feeling.

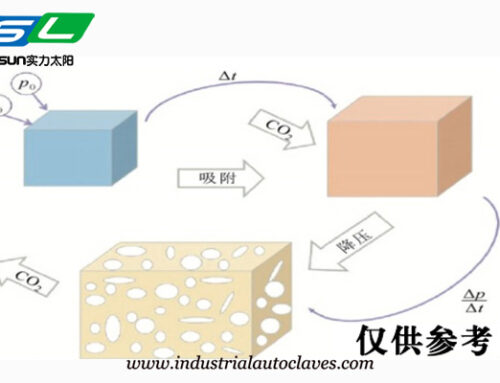

Do you know what the real supercritical fluid is like? Nitrogen heating up and pressed above the critical point, nitrogen fluids began to penetrate inside the raw materials. After insulation and pressure, the material expanded sharply after the pressure was quickly degraded.

Why is nitrogen foaming more common at present? It is because the nitrogen diffusion coefficient is similar to the air. And the product size is relatively stable and it is not easy to shrink. Now most of the plate foam and shoe material foaming are excellent in key properties such as cushioning and rebound rate. Let ’s briefly decrypt: first place the cross -linking plates, sheets, and shoe materials on the material vehicle, promote the high -pressure kettle, and turn off the high -pressure kettle door.

Inject supercritical nitrogen into the kettle, heat in the kettle, pressurize, so that the supercritical fluid reaches the preset temperature and pressure. The high -pressure fluid continuously spreads to the polymer matrix until the dissolving balance is achieved. And then the corresponding time is performed according to the process conditions. Inspection of insulation, and finally the need for foaming products quickly to get the need to get pressure.

Tai’an Strength Equipments Co., Ltd. invested enough manpower and material resources, developed and manufactured supercritical foam equipment with stable technical performance, and established a supercritical foam laboratory. Welcome to the supercritical midsole foaming technology in the bottom of the manufacturer to discuss it together!

About STRENGTH Equipments

Taian STRENGTH Equipments Co., Ltd is the professional pressure vessel designer, manufacturer and exporter dedicated in supplying finest quality industrial autoclave, storage tank and dish head products and solutions to worldwide customer over 20 years. We have over 80 talented research and development experts, 2 million square meters manufacturing factory and more than 50 sets large-scale manufacturing machines. Our annual industrial autoclave and storage tank output can reach over 300 sets, dished head output can reach over 3000 sets.

STRENGTH Equipments is not only manufacturing high quality industrial autoclaves, storage tanks and dished ends but also providing custom product design, fabrication and after-sale service. ODM, OEM are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.