- Materials: Carbon Steel, Stainless Steel, Alloy Steel, Clad Steel, Dual-phase Steel, Eec.

- Fabrication Method: cold dishing and flanging or hot pressing.

- Dimensions: up to 26,000 mm diameter and 200mm thickness.

- Edge preparation: according to your requirement.

- Approval: ASME.

- Inspections: by LR, TÜV, BV, SGS, or other inspection companies.

- Certifications of ASME U, ASME U2, NB, PED(CE),ISO9001, ISO45001, ISO14001.

Conical Head

Description

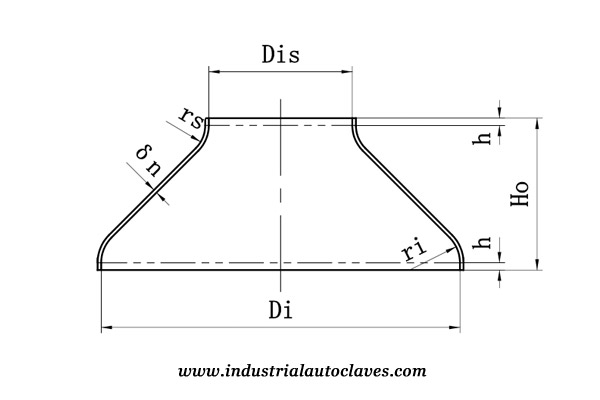

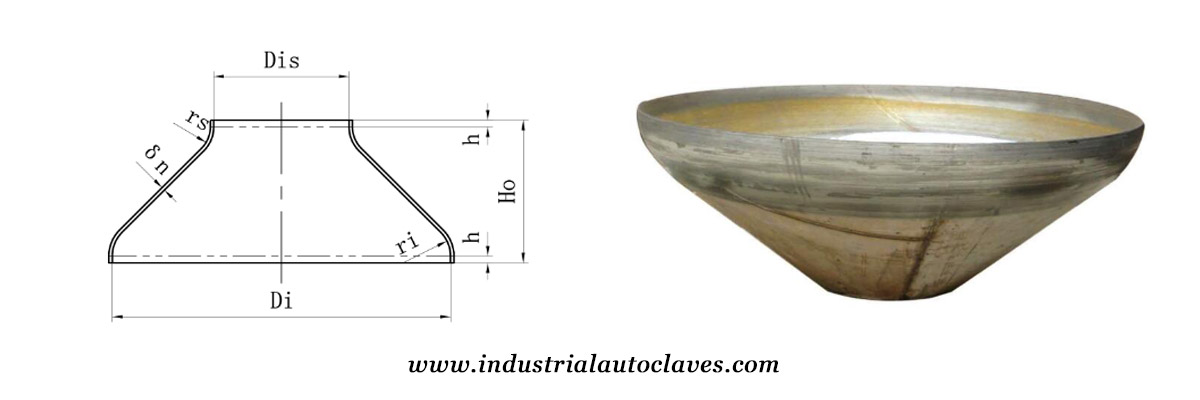

Conical Head (also called the tapered tank head) is widely used for vessel bottom or cover plates. Our asme conical head is often made with carbon steel, stainless steel, austenitic and non ferritic metals that can be cold worked. With the shape of concentric cone, the conical head consists of a large end cone and a small end. Cone and large end of the connection, due to geometric discontinuity, the radius of curvature of the mutation, so there will be a large lateral thrust, causing a large edge stress, prone to bending, it is necessary to strengthen.the tapered head The cone head type is divided into CHA (30), CHA (45), CHA (60) by half angle. According to the size of the end of the type is divided into non-folding conical tank head and hemming conical dished head.

conical head of strength equipments

Conical Head Specifications

| Conical Head Specifications of TAIAN STRENGTH | |

| Materials | Carbon Steel, Stainless Steel, Alloy Steel, Clad Steel, Dual-phase Steel, Etc. |

| Forming Way | Colding forming or Heat Forming |

| Diameter | 500mm~260,000mm |

| Thickness | 5mm~300mm |

| Molding Method | Intergral forming or Split Welding |

| Edge preparation | According to Requirement |

| Manufacture Standard | ASME or China Standard |

| NDT | Visual Test, PT, RT, UT, MT |

| Third Party Testing | LR, TÜV, BV, SGS,etc. |

| ※ Other customization is acceptable | |

conical-head-of-strength-equipments

Applications of Conical Head

STRENGTH Equipments can produce up to 8,000 mm diameter asme conical head depending upon thickness of material and wall thickness up to 20 mm depending upon material and diameter. custom forms and dimensions are also available.

The conical head is applied for the bottom of the pressure vessel to facilitate the collection and removal of internal materials and for the connection of two-stage vessels of varying diameters (also known as variable diameter sections).

About STRENGTH Equipments

Taian STRENGTH Equipments Co., Ltd is the professional pressure vessel designer, manufacturer and exporter dedicated in supplying finest quality industrial autoclave, storage tank and dish head products and solutions to worldwide customer over 20 years. We have over 80 talented research and development experts, 2 million square meters manufacturing factory and more than 50 sets large-scale manufacturing machines. Our annual industrial autoclave and storage tank output can reach over 300 sets, dished head output can reach over 3000 sets.

STRENGTH Equipments is not only manufacturing high quality industrial autoclaves, storage tanks and dished heads but also providing custom product design, fabrication and after-sale service. ODM, OEM are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.