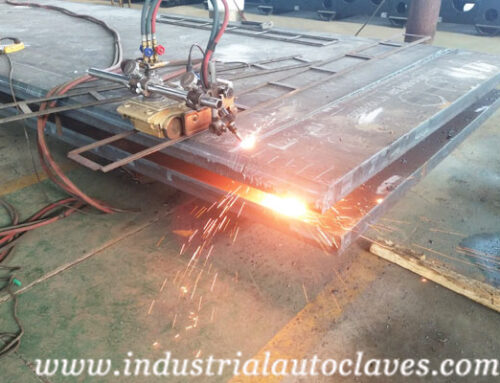

Pressure vessel welding is a process in which two separate pressure vessel iron and steel objects are combined to form a whole by combining atoms (molecules) with the help of energy. Most of the materials used to make pressure vessels are steel. And most of them are ordinary carbon steel and low-alloy structural steel. At present, the main methods of pressure vessels welding include manual arc welding, gas shielded welding. Such as self-shielded arc welding, submerged arc welding, spot welding and so on.

(1) Manual arc welding

The welding method that relies on the heat of the arc is called arc welding. Manual arc welding is a kind of arc welding that uses a manual electrode to weld. And it is the most commonly used method in pressure vessel welding.

The principle of manual arc welding, the electrode and the weldment are two electrodes that generate an arc. Moreover, the arc generates a lot of heat to melt the electrode and the weldment. The end of the electrode melts to form a droplet, which transitions to the base metal of the molten weldment to fuse. Then forming a molten pool and undergoing a series of complex physical-metallurgical reactions. As the arc moves, the liquid molten pool gradually cools and crystallizes, forming a weld.

(2) Gas shielded arc welding

The gas shielded electric welding used in the pressure vessel welding is also called molten electrode gas arc welding. Pressure vessel welding uses the welding wire and the weldment as two poles. The arc heat is generated between the two poles to melt the welding wire and the base metal of the weldment. At the same time, the shielding gas is sent to the welding area. Separate the arc, the molten welding wire, the molten pool and the nearby base metal from the surrounding air. Afterwards, the welding wire is automatically fed in, continuously melted under the action of the arc. Then merged with the molten base metal to form a weld metal.

Furthermore, this pressure vessel welding method is referred to as GMAW (Gas Metal Arc Welding) due to the difference of shielding gas. It can be divided into CO2 gas shielded arc welding. In fact, it is the most widely used welding method at present. It is characterized by the use of large current and thin welding wire, which has fast welding speed, large penetration depth and high operating efficiency.

(3) Self-shielded arc welding

Pressure vessel welding self-shielded arc welding was once called pressure vessel non-gas-shielded arc welding. Compared with gas shielded arc welding, the wind resistance is better. When the wind speed reaches 10m/s, the weld with no porosity and superior mechanical properties can still be obtained. Due to automatic welding, the welding efficiency is extremely high. The welding torch is light and does not use gas cylinders, so the operation is very convenient, but the price of welding wire is higher than that of CO2 shielded welding.

(4) Submerged arc welding

Pressure vessel wedling submerged arc welding is a kind of arc welding in which the arc burns under the cover of meltable granular flux. The bare welding wire continuously fed into the molten pool is not only a metal electrode, but also a filler material. The arc burns under the flux layer to melt the wire and base metal to form a molten pool. The molten flux turns into slag, which covers the surface of the molten metal pool to separate the high-temperature molten pool metal from the air. In addition to the protective effect of the flux forming slag, it also participates in the metallurgical reaction with the molten metal. Thereby affecting the chemical composition of the weld metal.

In a word, the above are the more common pressure vessel welding methods for pressure vessels. With the help of different welding techniques, we can meet the technical requirements of different pressure vessels welding. In order to better guarantee the quality and improve the safety factor.

About STRENGTH Equipments

Taian STRENGTH Equipments Co., Ltd is the professional pressure vessel designer, manufacturer and exporter dedicated in supplying finest quality industrial autoclave, storage tank and dish head products and solutions to worldwide customer over 20 years. We have over 80 talented research and development experts, 2 million square meters manufacturing factory and more than 50 sets large-scale manufacturing machines. Our annual industrial autoclave and storage tank output can reach over 300 sets, dished head output can reach over 3000 sets.

STRENGTH Equipments is not only manufacturing high quality industrial autoclaves, storage tanks and dished ends but also providing custom product design, fabrication and after-sale service. ODM, OEM are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.