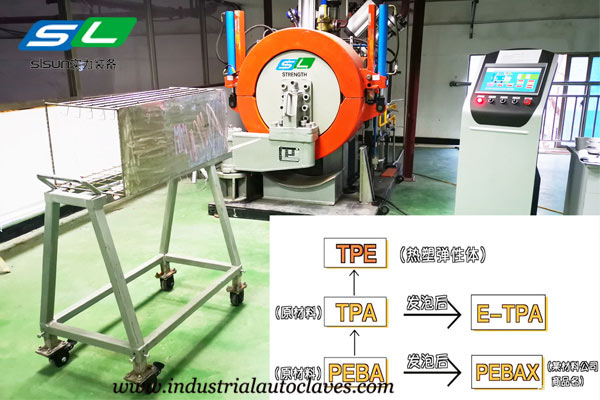

There are many supercritical physical foaming material, such as eva, tpu, tpee, pe, pebax, etc. These raw materials cannot be foamed by a single particle, and there must be a production process to achieve supercritical foaming conditions

What is the production process of supercritical physical foaming material? Now let’s learn this together.

Step 1: Mix the ingredients

Mix, extrude, and pelletize raw materials such as tpu, eva, tpee, pe, pebax and other required additives (excluding foaming agent) using mixer + extruder + pelletizing equipment.

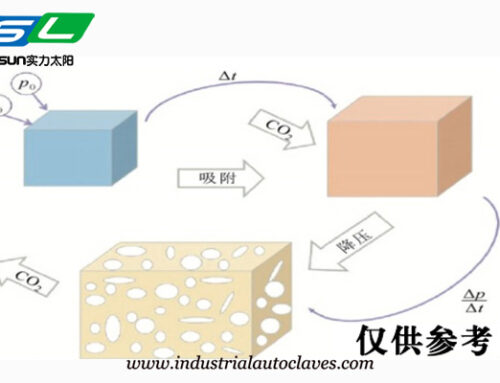

Step 2: raw material impregnation

Fill the mixture particles into an autoclave, impregnate supercritical carbon dioxide or nitrogen, or a mixture of the two, and then release the pressure to foam to obtain a foamable material.

Step 3: extrusion injection molding, heating molding

Injection molding, the structure is similar to that of an extruder. The raw material is heated and softened. Using the injection machine, it is injected into the midsole mold through the channel, just like the extrusion of a syringe, and then heated and formed.

Step 4: supercritical foam material cold billet

Step 5: One-time high-pressure foam molding

Put the supercritical foam material cold billet in the material frame, send it into the autoclave, inject supercritical fluid (nitrogen or carbon dioxide or mixed gas), raise the temperature and pressure, and keep the temperature and pressure for a certain period of time according to the process conditions , and then quickly exhaust and release the pressure, the supercritical physical foaming material will be foamed.

The above is based on years of communication with customers, summed up the experience. For deficiencies, experts in the supercritical physical foaming material industry are invited to correct and guide.

Taian Strength Equipments is a designer and manufacturer of supercritical foaming equipment, which can provide a one-stop solution for supercritical foaming. The company has a supercritical physical foaming material laboratory, which can provide you with incoming material testing!

Supercritical foaming equipment – Strength equipment looks forward to serving you!

About STRENGTH Equipments

Taian STRENGTH Equipments Co., Ltd is the professional pressure vessel designer, manufacturer and exporter dedicated in supplying finest quality industrial autoclave, storage tank and dish head products and solutions to worldwide customer over 20 years. We have over 80 talented research and development experts, 2 million square meters manufacturing factory and more than 50 sets large-scale manufacturing machines. Our annual industrial autoclave and storage tank output can reach over 300 sets, dished head output can reach over 3000 sets.

STRENGTH Equipments is not only manufacturing high quality industrial autoclaves, storage tanks and dished ends but also providing custom product design, fabrication and after-sale service. ODM, OEM are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.