Horizontal carbon fiber autoclave(also called composite autoclave) is a mechanical equipment which changes the prepreg structure by means of high temperature, high pressure and other technical means to achieve the curing molding process standard. Composite autoclave can be used for metal/non-metal bonding components and resin based high strength glass fiber, carbon fiber, boron fiber, aramid fiber and other composite materials products, such as aircraft doors, fairing, airborne radome, bracket, wing, tail, etc.

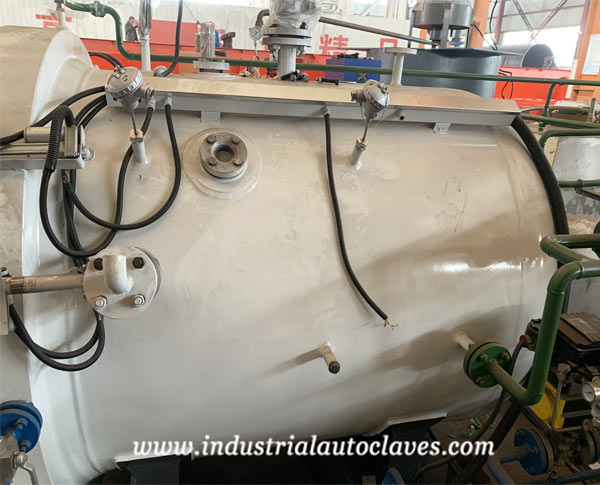

Recently, the horizontal carbon fiber autoclave customized by Tianjin customer was successfully delivered. In addition to the conventional requirements, the customer required the working temperature of the composite autoclave to be 380℃. As we all know, the working temperature of conventional composite autoclave is about 200℃. The requirement of 380℃ is far higher than the normal working temperature of horizontal carbon fiber autoclave. The customer also knows that this requirement is special and has high technical requirements. Therefore, it has been emphasized for many times and we are required to prove that we can produce composite autoclave with the requirements of the customer. We can fully meet the customer’s requirements. In order to reassure the customer, we took out the technical parameters and drawing of composite autoclave with the same 380℃ requirement that we did before for the customer’s technical staff to check and verify, and finally got the customer’s recognition and trust.

The horizontal carbon fiber autoclave also adds the function of sight glass, in order to conveniently check the appearance changes of the experimental products in composite autoclave at any time.

Parameters of DN1200*1200mm Composite Autoclave | ||

| No. | Item | Parameter |

| 1 | Effective Diameter | 1200mm |

| 2 | Effective Length | 1200mm |

| 3 | Working Temperature | 380℃ |

| 4 | Working Pressure | 1.3MPa |

| 5 | Vacuum Lines | 2ea. |

| 6 | Quantity of Thermocouples | 2ea. |

| 7 | Power Supply | 380 V, 50 Hz, 3 phase |

After the production of the carbon fiber autoclave was completed and the inspection reached the standard, the customer came to our factory for inspection in middle of May, and gave a high evaluation of our technology and product quality. The equipment has successfully arrived at the customer’s site at the end of May this year.

About STRENGTH Equipments

Taian STRENGTH Equipments Co., Ltd is the professional pressure vessel designer, manufacturer and exporter dedicated in supplying finest quality industrial autoclave, storage tank and dish head products and solutions to worldwide customer over 20 years. We have over 80 talented research and development experts, 2 million square meters manufacturing factory and more than 50 sets large-scale manufacturing machines. Our annual industrial autoclave and storage tank output can reach over 300 sets, dished head output can reach over 3000 sets.

STRENGTH Equipments is not only manufacturing high quality industrial autoclaves, storage tanks and dished ends but also providing custom product design, fabrication and after-sale service. ODM, OEM are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.